Rigid Flexible PCBs — a Mix of the Two Best PCBs

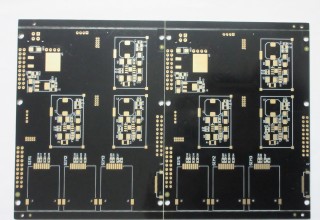

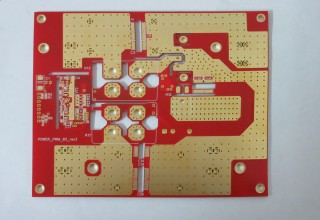

LOS ANGELES, August 30, 2017 (Newswire.com) - POE Precision Electronics is all set to introduce their latest assembly in PCB manufacturing: the rigid, flexible PCBs. For individuals who have always wondered if the benefits of the flexible PCB and the rigid PCB can be combined in one new PCB, these rigid, flexible PCBs by POE are exactly what they've always wanted.

These rigid, flexible printed circuit boards offer many more advantages than all the other PCBs, because these combine the benefits of both the flexible PCB and the rigid PCB, as mentioned before. To give a brief overview of some of these advantages mentioned above, here are some examples: better signal transmission, more stability, improved quality control and higher density applications. The overall size and weight of these printed circuit boards provided by POE Precision Electronics are also decreased. Rigid boards weigh more and come in larger packet sizes, but combine the rigid PCB with the flexible PCB results in the reduction of weight and a smaller package size. Decreased weight and size also help with cost effectiveness by reducing shipment costs.

Fewer components are required — another incredible benefit of the rigid, flexible PCBs. When an ordinary rigid board is compared with the rigid, flexible PCB, it can be seen that the rigid, flexible PCB has fewer components and minor interconnections. This means decreased hassle of ordering all the different parts, tracking them and testing and inspecting them. It also helps minimize the cost of spending on such components, thereby helping individuals save money. Fewer interconnections also mean fewer connections that could destabilize and cause potential problems. Hence, as mentioned before, rigid, flexible PCBs also aid customers by providing greater stability.

In a rigid, flexible PCB, the circuitry on the circuit board is made of many layers of a flexible circuit. Since this kind of PCB is just two different circuits in one new circuit, kind of like a two-in-one, these two circuits have to be connected somehow too. This is done by plated thru holes. Many readers might be thinking that it's possible to connect the two circuits in a lot of different ways, kind of like a Mix on Match. While that is true, individuals shouldn't have to waste time doing that by them. So POE Precision Electronics makes sure to offer customers three of the most commonly used rigid flex combinations that will surely serve all of their requirements. The rigid, flexible PCBs come down to an excellent balance between the rigid PCB and the flexible PCB. At areas where more support is required, that is where the designs are made more rigid. And at places where the requirement becomes needing extra space, the designs are more flexible.

Source: POE Precision Electronics Co., Ltd.