DP Technology Uses HOOPS Exchange to Keep ESPRIT on the Cutting Edge

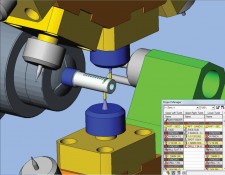

BEND, Ore., July 23, 2018 (Newswire.com) - Tech Soft 3D, leading provider of development toolkits to the engineering software industry, today announces DP Technology is using HOOPS Exchange to ensure their flagship product, ESPRIT, a full-spectrum CAM product, can successfully work with multiple CAD file formats and geometry types. The importance of data integrity led DP Technology to choose HOOPS Exchange. The leading CAD translation software development kit (SDK), HOOPS Exchange delivers access to over 20 CAD file formats through a single interface.

“We put HOOPS and other potential vendor solutions through a rigorous testing process with hundreds of test files,” said Ivan Krstic, Director of Product Marketing for DP Technology. “We found HOOPS to have high import quality across all the CAD file formats, with a very fast loading time, and very low memory usage. Integrity of CAD data input is critical for a CAM system in general. For an application like ESPRIT that sees such a mix of CAD formats and geometry types, it’s essential. If the model quality is poor, the quality of the manufactured part will be poor. When we were evaluating data exchange partners, it was very important to us to find one that could properly support all the different CAD formats and geometry types.”

We found HOOPS to have high import quality across all the CAD file formats, with a very fast loading time, and very low memory usage. Integrity of CAD data input is critical for a CAM system in general. For an application like ESPRIT that sees such a mix of CAD formats and geometry types, it's essential. If the model quality is poor, the quality of the manufactured part will be poor. When we were evaluating data exchange partners, it was very important to us to find one that could properly support all the different CAD formats and geometry types.

Ivan Krstic, Director of Product Marketing for DP Technology

As a result of using HOOPS Exchange, DP Technology was not only able to build robust data access and translation capabilities into ESPRIT, with native Parasolid interoperability and support for 20+ file formats, but also provide better support for emerging manufacturing workflows (such as hybrid manufacturing and additive manufacturing), and anticipate market needs around manufacturing and deploy functionality that meets those needs within months.

“We aim to provide our customers with total manufacturing flexibility,” explained Krstic. “Our customers use ESPRIT for more than high-performance machining – they also use it for hybrid manufacturing and additive manufacturing processes like 3D printing. That means our solution has to work with general formats like DXF/DWG, IGES, VDA, ACIS, Parasolid, STL, STEP, 3D PDF, and JT; native formats like Inventor, Solid Edge, SolidWorks, Rhino, Catia, UG-NX, and Creo; and a combination of geometry types, including solids, surfaces, wireframe, and tessellated.”

Another key factor in DP Technology’s decision was HOOPS Exchange’s native Parasolid kernel interoperability. This direct data access maintains Parasolid data integrity, guaranteeing data is pristine and untouched, with no translation.

“ESPRIT has been Parasolid kernel-based since 1998,” said Krstic. “The fact that HOOPS Exchange had native Parasolid kernel interoperability was a huge selling point. It was also important to us to have some kind of data healing available, so the integration with Parasolid Bodyshop was an added benefit.”

HOOPS Exchange provides access to a broad range of data including boundary representation (B-Rep), product manufacturing information (PMI), model tree, views, persistent IDs, styles, construction geometry, visualization and more – all without depending on any CAD system. This wide-ranging access proved to be another important element in DP Technology’s decision-making process.

“We liked that HOOPS Exchange can provide access to the native CAD feature tree,” said Krstic. “Our product has a function called ESPRIT FX, which stands for Feature Exchange. It brings the feature tree from the CAD model over to ESPRIT, enabling a CAM programmer to better understand the design intent of the engineer. We wouldn’t be able to offer this function without a toolkit as sophisticated as HOOPS Exchange.”

After selecting HOOPS Exchange, DP Technology was rapidly able to start reaping the benefits of its decision by integrating the technology into its product and bringing it to market.

“Beyond the functionality itself, what’s impressive about HOOPS Exchange is how quickly we were able to integrate it and deploy it in ESPRIT,” said Krstic. “It only took a couple short months. Two versions of ESPRIT that use HOOPS Exchange were successfully released last year, and we look forward to continuing to put HOOPS to good use in the coming year.”

DP Technology is the provider of ESPRIT, a full-spectrum CAM system for CNC programming, optimization, and simulation. From its 18 worldwide offices across 8 countries, DP Technology serves customers in a variety of industries – many of whom work with multiple CAD tools and file formats as part of their workflow.

About Tech Soft 3D

Tech Soft 3D is the leading global provider of development tools that help software teams deliver successful applications, as well as the creator of the 3D format that is part of the PDF standard. Established in 1996 and headquartered in Bend, Oregon, Tech Soft 3D also has offices in California, France, England, and Japan. The company’s toolkit products power nearly 500 unique applications running on hundreds of millions of computers worldwide. For more information, visit www.techsoft3d.com or www.techsoft3d.com/CAM.

HOOPS is a registered trademark of Tech Soft 3D. All other products or company references are the property of their respective holders.

Media Contact: Angela Simoes, 415-302-2934, angela@techsoft3d.com

Source: Tech Soft 3D