Solid-State Automotive Lidar: What Does It Take to Commercialize Photonic Beam Steering, Asks IDTechEx

BOSTON, January 22, 2020 (Newswire.com) - The lidar technology landscape is very confusing, given the high level of technology choices available. Indeed, this confusion has exhausted the decision-making abilities of many organizations that spend endless hours debating which lidar technology to back. The fact that more than 100 organizations are developing different lidar technologies has further complicated the situation.

Si photonics can be used in many aspects of lidar design. In emerging FMCW lidars, Si photonics can be used in coherent receivers. Interestingly, Si photonics can be used to implement beam steering technology using optical phase array (OPA) technology, thus replacing the bulky rotating mechanical beam steering mechanism with a miniaturized true solid-state solution.

This would help miniaturize lidar modules, extend product lifetimes, and put lidars on a cost-reduction path akin to other solid-state technologies. This approach would replace many free-space optical components with chip-scale solutions and would create a fabless-foundry ecosystem akin to what is found in CMOS devices. This Si photonics technology can also greatly benefit from the advances made in the optical communication industry.

Many companies have significantly invested in Si photonics OPA lidars. The path to designing and manufacturing a high-performance automotive OPA lidar using this technology is, however, not straightforward. In this article, IDTechEx outlines and discusses many difficult design and manufacturing choices and highlights some of the technical constraints that this beam steering technology will likely face.

This article draws from IDTechEx's report “Lidar 2020-2030: Technologies, Players, Markets & Forecasts”. This report reflects their deep and comprehensive analysis of the lidar technology and business landscape. They have studied all the available technology options, assessing their merits, challenges, readiness level, and constrains of performance levels. IDTechEx has constructed technology roadmaps, showing how the competition between various lidar technology is likely to play out over time.

Furthermore, this report covers more than 100 entities working on lidar technology, offering investment and company formation trend analysis by technology/region, data-driven performance maps of lidar prototypes and products, enabling one to ascertain performance trade-offs and constraints of various technologies, critical interview-based company profiles, and histograms quantitatively demonstrating the existing or emerging popularity of each technology choice at each lidar component level. Finally, this report offers detailed price evolution projections for each technology and detailed market forecasts in unit numbers and value segmented by different ADAS and autonomous mobility functions and by different lidar technologies.

Technology choices and their consequences: from wavelength to material selection to design

Most Si photonics technologies are based on SOI technology. Here, a silicon or a silicon nitride layer is sandwiched by two silicon oxide claddings. The core layer (Si or Si3N4) acts as a waveguide, given its refractive index mismatch with silicon oxide (note: an Si layer with 220nm thickness with 5um buried oxide is in general selected). Note that the foundry ecosystem for SOI-based photonics is expanding. The table below outlines some research institutes and companies with notable capabilities. This is by no means an exhaustive list.

- Research entities: IME (Belgium), IME (Singapore), AIM (USA), Chinese Academy of Science (China) etc.

- Companies/Foundries: GlobalFoundries (USA), STMicro (Swiss, Italy, France), TowerJazz (Israel), TSMC (Taiwan), AMF (Singapore)

An important choice is that of the wavelength. Most lidars today are based on the ToF (time of flight) principle. These ToF lidars often operate in the NIR range (e.g., 850nm or 905nm). This is selected because sensitive, high-SNR, mature, Si-based avalanche photodiode (APD) and single-photon, avalanche photodiode (SPAD) are readily available. A downside for this wavelength is that the maximum permissible energy (MPE) level of the laser is constrained. This will likely require short nanosecond pulses of high-power laser but will, nonetheless, ultimately limit the range.

The other choice is to operate in the SWIR range, e.g., 1550nm. This wavelength has an MPE level which is orders of magnitude higher but requires the use of non-silicon receivers. Most lidars utilizing the FMCW (frequency-modulated-continuous-wave) principle use this wavelength. Note that FMCW offers velocity information per frame, higher SNR, lower power consumption, and less susceptibility to interference, but it is more difficult to implement because it requires a highly coherent stable tunable laser, a coherent optical mixer, and so on.

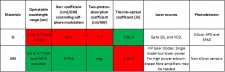

The first consequence of the wavelength choice is on the material selection: silicon or silicon nitride. The table below offers a high-level comparison between these two technologies. Silicon absorbs wavelengths shorter than 1.1um. It therefore precludes NIR operation and the associated benefits such as Si-based APD or SPAD detectors. In contrast, silicon nitride has a wide bandgap and, thus, enables both NIR and SWIR operation.

Silicon suffers from higher non-linearities compared to silicon nitride. In particular, two-photon-absorption (TPA) can become important in high-power operations given silicon’s relatively high TPA coefficient. In contrast, silicon nitride does not suffer from TPA. Silicon can also suffer from self-phase modulation (SPM) because its Kerr coefficient is an order of magnitude larger than silicon nitride. These non-linearities particularly manifest themselves at high power levels. As a result, silicon nitride OPAs are often used with ToF which requires high pulse power and silicon OPAs with FMCW which operates with much lower laser power levels (note: laser coherence length can limit range in FMCW).

Not all, however, is perfect with silicon nitride. In order to steer the beam, a phase shift between different elements of the array must be introduced. To achieve this, the refractive index of the substrate, i.e., silicon or silicon nitride, must somehow be changed. Two effects are commonly deployed: (1) change of temperature and (2) change in free carrier concentration. In general, the first has a smaller footprint by an order of magnitude but is slower by several orders of magnitude. In the first case, a heating element is introduced. This can either be a TiN strip, a polysilicon strip, or a doped waveguide. The former two are less efficient and slower but cause lower optical degradation. In this second case, a PIN diode is used.

A major challenge with silicon nitride is that its thermo-optical coefficient is an order of magnitude lower than silicon. As such, high heat must be introduced. This will cause severe heat management issues whilst also slowing the system down, as cooling is normally passive limited, e.g., passive single-sided cooling since the top side must remain transparent. In general, some 10-20 mW/π is required per phase shifter. Given the high required number of phase shifters, the heat management can become challenges especially in silicon nitride system (note: some major companies have selected this material to benefit from better laser sources and receiver technologies, but must grapple with the heat management and slowness side-effects).

The wavelength choice also impacts the laser source. For NIR (850nm, 905nm), relatively low-cost GaAs EEL and VCSEL sources are available. Both technologies can achieve hundreds of watts of peak power by either stacking (EEL) or implementing an array (VCSEL). Both lasers, however, lack highly collimated wavefronts. As such, coupling them into waveguides entails high loss.

Diode EELs are also available at 1550nm thanks to the telecom industry, e.g., InP. Such lasers are single mode, meaning that waveguide coupling can take place at high efficiency. The power level is, however, low, meaning that the FMCW (not ToF) principle is likely to be implemented. This partly explains why multiple firms selecting SWIR silicon OPA lidars use FMCW. Of course, fiber lasers, such as erbium-doped fiber amplifiers, can be used but they are bulky and expensive. Despite this, some companies are utilizing fiber lasers. For more details, please see www.IDTechEx.com/Lidar; this report includes a detailed analysis of all detector and laser source technology, offering detailed quantitative benchmarks and technology evolution trends. It examines well more than 100 3D lidars to extract trend information about which laser or detector technologies are employed.

Design challenges and considerations

The design of the OPA beam-steering component itself is also challenging. A high degree of beam coherence is required to meet the angular resolution requirement of 0.1 in the automotive industry. This requirement stems from the need to resolve the width of a human body at 150-200m. In mechanical or MEMS beam-steering, aspheric lenses are used to achieve the required full-beam divergence angle. In a photonics OPA operating at 1550nm, an aperture ratio around 1.13mm may be required. The beam steering angle is controlled by aliasing effects and diffraction limit envelope. Assuming that first-order aliasing effects are the first limiting factor, we arrive at an antenna spacing of 1.15*wavelength, i.e., 1.8um for 1550nm. As such, one can see that more than 600 antennas may be required.

Evidently, each antenna will require its phase to be controlled and shifted, leading to significant system complexity. Furthermore, assuming that for silicon each phase shifting requires 10 mW then the beam steering alone will consume 6W. This will be much higher for silicon nitride. The heat dissipation will become a challenge especially as the chip can only be cooled from one side and as most prototypes today use wire-bonding.

Evidently, 2D steering using the OPA principle will become too complicated. The largest 2D array demonstrated, I believe, is only 8x8. To achieve 2D steering, the wavelength is often varied. In general, 0.15-0.3deg/nm of steering in the perpendicular direction can be achieved using wavelength turning. As such, to achieve 20-30deg, a laser that can rapidly be tuned across a 100-200nm range will be required. Such lasers will likely be too expensive.

Yet another challenge is where to place the phase shifter drivers. These are, today, placed off-chip, meaning that they need to be connected. The easiest connection method would be to use wire-bonding, but the number of possible connections scales with the perimetry and not the surface of the chip and is, thus, limited. It might be possible to reduce the drivers by coupling some phase shifters, but the challenge here is that the initial phase at each phase shifter is unknown due to manufacturing variations. As such, it is likely that each, or at least nearly each, phase shifter will require a controller. In the longer term, IC-integrated photonics may become possible, but today this technology is not sufficiently mature.

Future outlook for photonics in lidar

We have seen that photonics-based OPA is highly promising, but requires further extensive technology development. Its design will also entail difficult technology choices. Our report “Lidar 2020-2030: Technologies, Players, Markets & Forecasts” offers a market forecast segmented by beam steering technology. This forecasts factors in the technology benefits and challenges, the performance levels and constraints, and the readiness level of OPA. It develops price projections as well as unit sale deployment of lidar technologies for each beam steering mechanism including MEMS, OPA, rotating mechanical, non-rotating mechanical, and others.

The use of photonics in lidars however is not limited to beam-steering. In fact, many are proposed to create an FMCW photonic circuit operating at 1550nm. This circuit, or as some call it, the ‘engine’, can consist of a tunable coherent laser, balanced photodetectors (e.g., Ge based), trans-impedance amplifiers, couplers, waveguides, etc. In other words, it can include all transceiver functions for coherence detection at 1550nm, enabling the rise of FMCW at SWIR wavelengths with all the benefits that it entails. In this modular approach, the choice of beam steering technology can remain open. To learn more about such approaches and companies, please visit www.IDTechEx.com/Lidar.

The market for lidar will grow. Despite some high-profile arguments to the contrary, IDTechEx believes that it is an indispensable part of the perception sensor suite for 3+ levels of autonomy, especially given its high angular resolution, long-range detection at night, and relatively dense point cloud (vs. current radar). Indeed, despite the projected rapid cost falls, IDTechEx's report forecasts the market to grow to $5.4 billion by 2030.

To understand how the market will evolve and how the composition between different beam-steering technologies, such as mechanical rotating, mechanical non-rotating, MEMS, different OPAs, and others will evolve, see IDTechEx's report “Lidar 2020-2030: Technologies, Players, Markets & Forecasts”. It provides detailed and comprehensive technology analysis, business landscape assessment, player profiles, and technology – and application – segmented market forecasts.

To find out more about Electric Vehicle research available from IDTechEx, visit www.IDTechEx.com/research/EV or to connect with others on this topic, IDTechEx is hosting: Electric Vehicle Materials, May 13-14, 2020, Estrel Convention Center, Berlin, Germany www.ElectricVehiclesEurope.Tech.

IDTechEx guides your strategic business decisions through its Research, Consultancy and Event products, helping you profit from emerging technologies. For more information on IDTechEx Research and Consultancy contact research@IDTechEx.com or visit www.IDTechEx.com.

Media Contact:

Jessica Abineri

Marketing Coordinator

+44(0)1223 812300

Source: IDTechEx