RASIRC Water Free Anhydrous Hydrogen Peroxide Demonstrates Five-Fold Increase in Hydroxyl Density

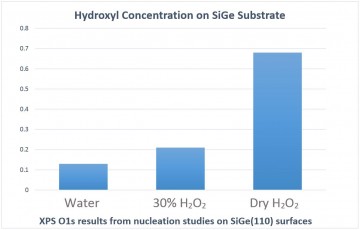

San Diego, CA, February 16, 2016 (Newswire.com) - RASIRC today released research results showing that anhydrous hydrogen peroxide gas enables a five-fold increase in surface hydroxyl density when compared to water in studies involving ALD nucleation on SiGe substrates. Hydroxyl density is an important factor in minimizing interfacial defects, increasing uniformity and improving next generation semiconductor device performance. BRUTE Peroxide provides a stable, reliable flow of anhydrous hydrogen peroxide for atomic layer deposition (ALD) and atomic layer etch (ALE). RASIRC products generate specialty gases from liquid sources to meet the demands of next generation semiconductor manufacturing.

Next-generation devices are moving from Silicon to Silicon-Germanium Channels. It is critical to form a stable uniform oxides without Si or Ge dangling bonds on the interface grown by ALD at low temperatures. “Research proves conclusively that the presence of water in some ALD and ALE processes negatively affects interfacial layer uniformity, leading to higher defect density, slower initiation, and degraded performance,” said Jeffrey Spiegelman, RASIRC President and Founder. “Tests of BRUTE hydrogen peroxide confirm that removing the water during processing with dry H2O2 enabled a three-fold improvement in hydroxyl density compared to 30 percent H2O2 and water source.”

"As thermal budgets are reduced, water fails to chemically react at the interface and physically adsorbs on the surface blocking active binding sites. Without the interference of water, anhydrous hydrogen peroxide can chemically react at interface layer, reducing the number of cycles needed to begin ALD growth at the surface."

Jeffrey Spiegelman, President and Founder

New Market Requirements

Semiconductor devices driven by Moore’s law are continuously becoming faster, smaller and more power efficient. Integration of new materials makes this possible, but requires new process steps for High K dielectrics in Gate Stack and FINFET. High aspect ratios limit the use of traditional oxidants. Plasma requires a line of sight often not available. Ozone can burn and damage delicate surfaces. Water is sluggish. Anhydrous hydrogen peroxide provides an alternative for functionalizing the surface with a dense layer of hydroxyl groups prior to deposition.

“As thermal budgets are reduced, water fails to chemically react at the interface and physically adsorbs on the surface blocking active binding sites. Without the interference of water, anhydrous hydrogen peroxide can chemically react at interface layer, reducing the number of cycles needed to begin ALD growth at the surface,” said Spiegelman. “Until now a safe method for storage, transport and delivery of anhydrous hydrogen peroxide has not been available. BRUTE Peroxide changes all that.”

Research Summary

Studies show that hydrogen peroxide is well suited for surface functionalization, because it is highly susceptible to splitting into two hydroxyl radicals on contact with surfaces. In contrast, water splits into one hydroxyl group and one hydrogen site on Ge surfaces, and may desorb leading to vacant dangling bonds (Kummel). Ozone is also problematic, where bridging metal-oxides and surface damage are typical.

Tests with SiGe(110) surfaces contrast the relative effectiveness of water, H2O/ H2O2 solution and anhydrous hydrogen peroxide. The results show that hydroxyl density increases as the proportion of water decreases. Hydroxyl density with anhydrous hydrogen peroxide is five-fold that for water and three-fold more dense 30 percent H2O2/ H2O solution.

A copy of the white paper presenting the research results “Anhydrous Hydrogen Peroxide Gas Delivery for Atomic Layer Deposition” is available for download here. For additional technical details, contact info@rasirc.com.

About BRUTE Peroxide

BRUTE Peroxide delivers anhydrous hydrogen peroxide gas from a liquid source in a sealed vaporizer. The liquid source combines hydrogen peroxide and a proprietary solvent. Only the hydrogen peroxide diffuses across a specialty membrane to flow to process with or without carrier gas. This device avoids the problems of micro-droplet formation, particle generation and incomplete carrier gas saturation endemic with traditional bubblers. BRUTE Peroxide is the only commercially available technology that can deliver up to 99.9% H2O2 gas by volume into vacuum.