PCM-Based System Heats Electric Vehicle Without Draining Battery

PLYMOUTH, Minnesota, May 25, 2016 (Newswire.com) - Cold climates pose a challenge for electric vehicles: With no engine to serve as a heat source, EVs rely on batteries alone to warm the cabin and defrost the windshield. Running the heater quickly drains batteries and can reduce driving range by as much as 60 percent. That can make a routine commute a frosty and mitten-biting affair in places like International Falls, Minn., where temperatures dip well below freezing on a typical January morning.

Using phase change material developed by Entropy Solutions, engineers at MAHLE, one of the world’s largest automotive suppliers, found a solution. They have developed a prototype of a thermal energy storage system that is expected to extend the range of EVs by 20 to 40 percent in cold conditions.

"Most organic based PCMs have latent heats of around 150 to 210 joules per gram. Water has a latent heat of around 330 joules per gram. I had always wondered if we could make an organic PCM that could beat water. We did it."

Dr. William R. Sutterlin, Chief Science Officer, Entropy Solutions

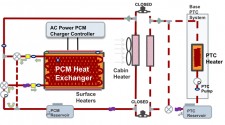

PCMs are substances that absorb and release thermal energy during the process of melting and freezing. The MAHLE system uses a PCM’s stored latent heat to provide cabin heating. The PCM is melted while the vehicle battery is charged from the electrical grid. The stored heat is transferred to the cabin as the PCM solidifies during driving. The system provides enough thermal energy to heat the cabin for about 46 minutes, the typical daily commute time for American drivers.

At the heart of the electrical PCM-assisted thermal heating system (ePATHS) is a high-efficiency PCM heat exchanger. Because heat transfer is a critical factor in system performance, MAHLE engineers chose a two-pass flow exchanger with a number of rectangular tube rows sandwiched between stacks of finned PCM chambers. An electric pump runs a water-glycol mixture through the PCM heat exchanger, absorbing heat from the PCM and flowing to a heater under the dashboard.

The design is similar to that of a standard automobile radiator, but with a fully enclosed PCM containment shell. The heat transfer fluid flows through channels in direct contact with the PCM chambers. The exchanger is enclosed in a high-performance vacuum insulation panel to minimize heat loss.

Entropy Solutions of Plymouth, Minn., developed two novel bio-based phase change materials to match the needs of the new system. The PureTemp PCM chosen, DPT83, has a melting point of 83° C (181° F) and a latent heat value of 348 joules per gram. DPT83’s relatively high latent heat capacity, well above the 200 J/g of older PCMs, helps minimize system size and weight. The 33-kilogram, 31-liter prototype includes 19 kg of phase change material.

Entropy researchers were able to synthesize the DPT83 beginning with natural vegetable-based feedstocks. They found that the PCM is compatible with aluminum and are conducting additional compatibility studies.

“Most organic based PCMs have latent heats of around 150 to 210 joules per gram,” said Dr. William R. Sutterlin, Entropy’s chief science officer. “Water has a latent heat of around 330 joules per gram. I had always wondered if we could make an organic PCM that could beat water. We did it.”

The $3.5 million, three-year collaborative research project, with 50 percent funding from the U.S. Department of Energy, is detailed in two technical papers published in April by SAE International, “Design and Testing of a Thermal Storage System for Electric Vehicle Cabin Heating” and “Thermal Storage System for Electric Vehicle Cabin Heating - Component and System Analysis.”

"The PCM-based thermal storage system provides a commercially viable technology to mitigate range anxiety of electric vehicles in the marketplace. We are working closely with vehicle OEMs to commercialize the technology in the near future," said Tim Craig, MAHLE's U.S. Advanced HVAC System manager.

For the latest news and research on phase change material and thermal energy storage, subscribe to Phase Change Matters, the award-winning weekly newsletter.

Source: Entropy Solutions LLC