Mid Power LED Chips Can't Stand the Heat

Bonita Springs, FL, September 28, 2016 (Newswire.com) - When it comes to high output LED lighting applications, mid power chips can’t stand the heat. As LED chip manufacturing is led by industry demand, there was an increasing demand for LEDs in consumer electronics applications such as televisions and monitors resulting in the creation of mid power LEDs. These applications are largely low-heat and are not focused on building an LED chip that is designed to withstand high temperatures making mid power LEDs the perfect low cost solution.

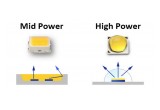

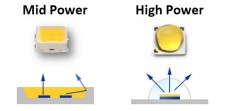

Recently, mid power LEDs have been used by high output lighting manufacturing due to the increased efficacy. The problem is, mid power LEDs are packaged in a plastic resin known as polyphthalamide (PPA) which has much less thermal performance and tolerance when compared to their high power counterpart’s ceramic LED packaging, leading to issues with the mid power chip’s integrity.

After comparison, it makes more sense to go with the high power LED system over the mid power LED system. Even though the efficacy is higher in mid power, at the same wattages much better lighting results are obtained with the optically controlled high power LED system.

John Burns, Manager of Sales and Marketing

PPA plastic yellows over time, especially when bombarded by powerful blue photons from the LED chips, resulting in greater absorption and loss of the light produced. As this light is absorbed, the PPA changes color over time and causes an observable color shift in the light emitted. This occurs as the discolored PPA absorbs the warmer spectrum of light, resulting in a cooler light emitted, shifting the overall color temperature over time. (1. Ralph Tuttle and Mark McClear, Cree Inc.)

Mid power chips are typically half the power (0.5 W) or less of the high power LED chips, so retrofit applications would require many more LEDs. Additionally, their plastic packaging cannot withstand the demanded higher temperatures necessary for high output lighting applications. Higher temperatures combined with the heating and cooling thermal cycles over time will lead to the plastic becoming brittle and cracking resulting in LED circuit failures.

While mid power LED chips may have a better lumens per watt ratio (l/W of ~100-120) than the high power LEDs, they don’t have nearly the same lumen maintenance or color stability when compared to their high power counterpart. While energy saving rebate programs such as the Design Lighting Consortium (DLC) place their value purely in the efficacy, they are ignoring critical factors that will lead to lighting loss, uneven lighting distribution, and failures in the field.

Currently, mid power LEDs may be drawing attention and rebates from their high efficacy, but the drawbacks overwhelm the benefits. From the sub-par plastic packaging that decreases the LED’s color temperature over time to the lower thermal limits that induce cracking of the LED packaging, they have proven their inability to be a reliable retrofit for traditional HID lighting applications. High output lighting solutions with mid power LEDs require more than double the amount of LEDs resulting in a overheating issues. Additionally, the large number of LEDs leads to products that do not support optical lensing for controlled light distribution that poses a set of photometric quality issues.

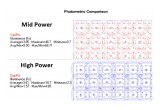

Photometric Comparison

The image below (see photometric comparison) shows the photometry with the exact same pole height, spacing, and wattage. The only difference is the type LED chip used. As you can see, the high power LEDs with optics create a much more uniform distribution of light. Compared with the mid power LEDs which have greater hot spots and dark spots in their light distribution along with the unwanted side-effect of light pollution due to their lack of directed optics.

In conclusion, Global Tech LED recommends for long term lighting solutions ( greater than five years ) to utilize high power LEDs. Global Tech LED is a leading manufacturer of Made-In-America LED lighting retrofits and fixtures which incorporate high power LEDs and customized optics for precise lighting distribution. Global Tech LED uses high power LED chips because they can withstand the higher temperatures ( greater than 50ºC ) required for retrofit applications and when combined with their on-board maintenance program and vortex heat-sink design we can ensure our LEDs output long-lasting and brightly uniform lighting.

Author: Robert Bender, Manager of Technology, Global Tech LED

Sources:

Ralph Tuttle and Mark McClear, Cree Inc. http://www.ledsmagazine.com/articles/print/volume-11/issue-2/features/sources/understand-the-true-cost-of-led-choices-in-ssl-systems-magazine.html

Michael Royer, PNNL, Chad Stalker, Philips Lumileds, Ralph Tuttle, Cree

http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/color-stability-webinar_4-15-2014.pdf

Philips Lumiled Luxeon T

http://www.lumileds.com/products/high-power-leds/luxeon-t

Source: Global Tech LED