LMI Technologies Officially Releases Gocator Firmware 5.0 and New Laser Profiler Hardware Version

VANCOUVER, British Columbia, April 17, 2018 (Newswire.com)

-

LMI Technologies (LMI), a leading developer of 3D scanning and inspection solutions, is pleased to announce the official launch of Gocator firmware 5.0. This release has a number of major developments that elevate Gocator to a new standard of visualization responsiveness. LMI is announcing a new hardware version of its Gocator 2100/2300 line profilers, offering over 2x the sensitivity of previous generations (details at bottom of page).

High-Definition 3D Visualizer

Gocator remains the leading 3D sensor product operating out of the box with only a web browser required to set up and deploy.

Chi Ho Ng, Director of Applications

Gocator 5.0 delivers a scalable, responsive, high-definition 3D data visualizer that can handle millions of 3D data points efficiently across all devices including mobile. Users get fast visualization that eliminates waiting for progress bar completion and operating in lower resolution modes that make working in 3D more productive and enjoyable.

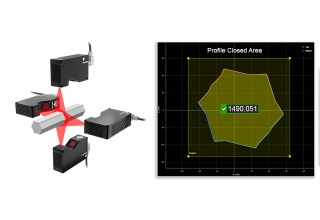

360º Ring Layout

Gocator 5.0 supports multi-sensor ring layouts (in addition to the existing wide, angled, opposing and reverse layouts). The ring configuration allows users to acquire a raw (i.e., unprocessed) 3D point cloud of the entire circumference of a scan target without losing any data points. Use measurement results from our new Profile Area tool to calculate total object volume.

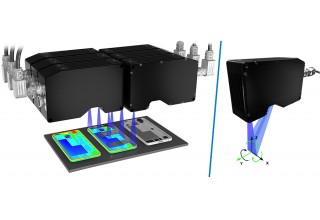

Multi-Sensor Alignment with 6 Degrees of Freedom (DoF)

Based on mechanical alignment, Gocator 5.0 delivers superior results that do not rely on geometry to achieve high repeatability.

“Our 5.0 release addresses a number of important customer needs while continuing to advance Gocator’s overall smart sensor usability. Leveraging the latest web technologies, Gocator 5.0 demonstrates that massive 3D point clouds can be easily manipulated within today’s browsers. Gocator remains the leading 3D sensor product operating out of the box with only a web browser required to set up and deploy,” said Chi Ho Ng, director of applications.

Other notable features in Gocator 5.0 include a new scan mode for snapshot sensors that deliver exceptional results for curved, shiny targets; multi-tool reordering and a Plane Geometric feature for high-repeatability point-to-plane measurements (ideal for consumer electronics applications).

New Gocator 2100/2300 D Version

LMI has increased the performance of its Class 2M (now Class 2) and Class 3R sensors. The improvements offer over 2x the sensitivity of previous generations and effectively lower laser classifications (from 3B to 3R in some cases and from 3R to 2 in many cases). This allows customers to scan darker targets at higher speeds without the safety considerations of class 3B lasers. D version sensors will take advantage of the new sensitivity improvements starting with Gocator 5.0.

Gocator 5.0 comes with every new Gocator®. Order the Gocator® 3D smart sensor now at contact@lmi3d.com for improved factory automation, inspection and optimization.

Already own a Gocator? Download firmware 5.0 for free here: www.lmi3d.com/support/downloads/.

About LMI Technologies

At LMI Technologies, we work to advance 3D measurement with smart sensor technology. Our award-winning, FactorySmart™ sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies. Unlike contact-based measurement or 2D vision, our product removes complexity and dramatically reduces implementation cost.

To learn more about how LMI’s inspection solutions can benefit your business, contact us at contact@lmi3d.com or visit us at www.lmi3d.com to explore the possibilities of smart 3D technology.

Media Contact:

Kassandra Sison

Marketing Manager

LMI Technologies

Tel.: +1 604 636 1011

E-mail: ksison@lmi3d.com

Source: LMI Technologies Inc.