Fiber Lasers: A Versatile Technology for Lightweighting, Battery Manufacturing and LiDAR in the Automotive Industry

IDTechEx forecasts the global fiber laser market to reach a size of $8.9 billion in 2028

BOSTON, June 28, 2018 (Newswire.com) - Recent advances in fiber laser welding are highly advantageous for lightweighting and battery manufacturing. Fiber lasers are reliable, compact and energy efficient systems that offer the best beam quality for applications where precision is important. The weight of a vehicle can be significantly reduced by minimizing the size of flanges with fiber laser processing. Meanwhile, beam delivery via an optical fiber ensures simplicity of integration into robotics. Consequently, process speed is maximized; material costs and operation costs are minimized. Learn more about the fiber lasers technology and market in the recent IDTechEx Research market report on the topic: Fiber Lasers 2018-2028: Technologies, Opportunities, Markets & Forecasts.

Fiber laser welding systems optimized for dissimilar metal joining are emerging as an essential tool for the electric vehicles market. Fiber lasers utilizing a wobble beam process produce strong and highly uniform weld seams without causing thermal damage to the surrounding materials. Key players developing fiber laser systems for battery welding include IPG Photonics (USA) and Trumpf (Germany).

Fiber lasers are reliable, compact and energy efficient systems that offer the best beam quality for applications where precision is important.

Dr Niliushi Wijeyasinghe, Technology Analyst, IDTechEx

Some fiber laser manufacturers are also preparing to enter the automotive light detection and ranging (LiDAR) market. Fiber lasers that operate in the 1.5 μm wavelength band are much safer for human vision than the 905 nm diode lasers used in conventional LiDAR systems. This eye-safe wavelength enables fiber laser LiDAR to operate at higher powers and offer long-range sensing for autonomous vehicles; superior resolution and full functionality with fewer lasers are additional advantages. As the technology is based on an optical fiber, the absence of free-space optics and mechanical components provides excellent system stability and long product lifetime. Luminar (USA) are a fast-growing LiDAR start-up commercializing this technology, and Volvo made a large investment in the company in June 2018. Toyota were the first automotive manufacturer to form a partnership with Luminar and began testing an autonomous vehicle with fiber laser LiDAR in 2017.

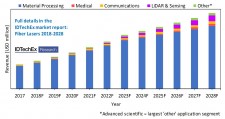

Technology consulting company IDTechEx recently published a market report titled ‘Fiber Lasers 2018-2028: Technologies, Opportunities, Markets & Forecasts’. The report provides a detailed analysis of fiber laser innovations that will have a major impact on the automotive industry within the next decade. In an upcoming free webinar on fiber lasers, technology analyst Dr. Nilushi Wijeyasinghe provides an overview of the key innovations driving growth in the material processing and sensing market segments. IDTechEx forecasts the global fiber laser market to reach a size of $8.9 billion in 2028.

Media Contact:

Charlotte Martin

Marketing & Research Coordinator

c.martin@IDTechEx.com

+44(0)1223 812300

Source: IDTechEx