AI Poised to Transform the Battery Industry, Reveals New IDTechEx Market Report

BOSTON, November 20, 2024 (Newswire.com) - The need for net-zero has led to an increasing pressure to achieve worldwide electrification, skyrocketing demand for rechargeable batteries. As the electric vehicle (EV) and battery energy storage system (BESS) industries grow, requirements for the batteries that power them become more demanding.

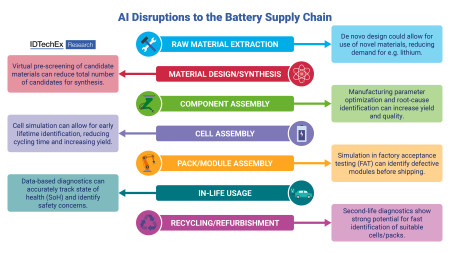

To achieve more energy-dense batteries that aren’t unsustainably expensive, faster battery development is needed, as well as more efficient management, manufacturing, and recycling methods. Artificial intelligence (AI) will play an important role in achieving these goals, as discussed in the recent report from market intelligence firm IDTechEx, “AI-Driven Battery Technology 2025-2035: Technology, Innovation and Opportunities.”

IDTechEx Technology Analyst Daniel Parr, co-author of the report, explains: “AI, especially machine learning (ML), has begun to be employed at multiple stages of the battery life cycle. The BESS and mobility industries are best poised to take advantage of these AI-driven technologies, and uptake has already been significant. In terms of in-life diagnostics and second-life assessment, the standard business model is third-party cloud-based diagnostics/second-life testing. The total capacity of cells supported by AI-assisted, cloud-based diagnostics has already reached 14GWh, and is expected to rise to over 190GWh by 2035.”

Meanwhile, the cell testing and materials discovery markets are split between in-house platforms and third-party cloud-based services. In terms of materials discovery, general materials informatics players have experienced significant interest and growth from the battery industry over the last few years. For cell testing, both general design-of-experiment optimization and battery-focused cell simulation have seen interest from battery component suppliers, battery developers and OEMs. It is likely that in-housing will become the norm for larger battery players, especially automotive OEMs, though third-party platforms may still be used as an auxiliary development stream.

For manufacturing, AI deployment comes in two forms. Parr explains that the first involves integration of a camera suite and image recognition and analysis software. This allows for defects to be caught immediately, preventing defect propagation and potentially allowing defective cells to be fixed before shipping. However, it is also more CapEx intensive. As such, it will likely be used only by larger players, with few start-ups investing in the technology. The second form involves machine-learning-assisted analytics for factory acceptance testing (FAT), which is a type of pre-shipping quality control test. This is less CapEx intensive, however faulty cells at this stage may be more difficult to fix. Instead, it allows for more reliable shipments from manufacturer to OEM.

IDTechEx predicts that by 2035, AI will be commonplace throughout the battery industry, but especially in cell development and manufacturing, and for applications in stationary energy storage systems and electric vehicles. Materials informatics and early-lifetime prediction are the most promising applications for AI and will form a major part of the solution to electrification needs and rising battery demand.

To find out more, see IDTechEx’s recent report, “AI-Driven Battery Technology 2025-2035: Technology, Innovation and Opportunities” – www.IDTechEx.com/AIBattTech.

About IDTechEx

IDTechEx provides trusted independent research on emerging technologies and their markets. For more information, contact research@IDTechEx.com or visit www.IDTechEx.com.

Source: IDTechEx